Slitter Winders

Features:

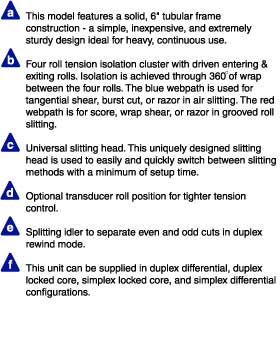

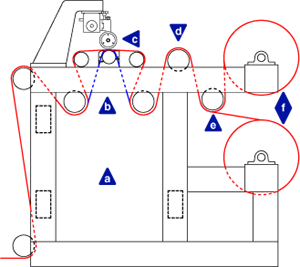

- Heavy duty construction

- Custom AC vector or DC digital, 1,2, or 3 drive systems

- Equipped with a universal four-roll cluster slitting station

- The cluster allows wrap or tangential slitting

- First and fourth rolls are driven

- The combined wrap is in excess of 360 degrees

- A draw between the two rolls assures smooth tension across the slitting knives

- Clamshell latches on lower slitting position allow a shear shaft, grooved roll, or score platen to be interchangeably mounted

- If differential winding is required, we offer the option of drive ring and spacer, cam lock, or pneumatic differential shaft technology

- Heavy duty, shafted, center unwind unit with tension control and optional edge guiding

|

Products

|

|

|

|

|

|

|

|

|

Back

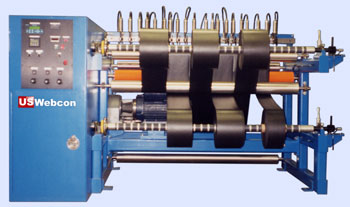

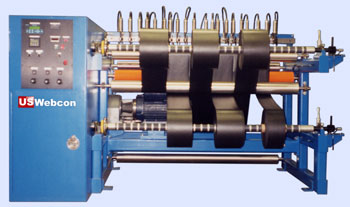

Center Driven Slitter Winder

The US Webcon Basic Slitter Winder was developed to fill an industry need

for reasonably priced machinery with sufficient control options to provide

high performance in a heavy duty production environment.

|

This particular unit was designed to unwind, slit and rewind various weights

(up to 4,000 lb. roll) of thermoplastic laminate. The process begins at

a single position, center driven unwind stand. The product proceeds through

the slitting knives and is rewound on a fully supported, two position differential

configuration rewind with ring and spacer technology. |

Options:

- Designed for medium or heavy applications

- Single or multi position winding

- Cantilevered or removable mandrel shaft options

- Locked core and/or differential winding

- Accommodates web width to 100"

- Single position rewind roll diameter to 40"; multi position to 30"

|