Narrow Web Unwind and Rewind Stands

US Webcon offers a extensive line of narrow web cantilevered unwind

and rewind stands. These winders are customizable to meet your production

needs with numerous features and options to fit your specific requirements.

Narrow Web Lab Rewind Stand

The cantilevered rewind stand positioned to the right was designed

as a 12" lab winder using combination casters with built in

step brakes that allow easy portability. The latest closed loop

load cell and magpartical clutch technology is used to control

web tension thru out the roll build. The web guider uses a dynamically

compensated edge detector with electric linear actuators along

with an intelligent control system that maintain an accurate

guide point over the entire production run.

|

|

|

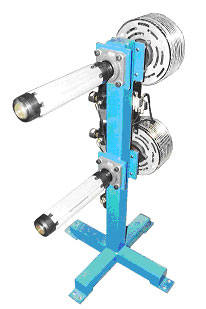

Dual Position Narrow Web Rewind Stand

The cantilevered winder on the left was designed as a 10" two

position production winder. This set up can be used to increase

production by alternating between winding positions. Unloading

the finished roll on one position while continuing to wind on

the other position. This machine can also be set up to wind

two webs simultaneously. Each position is supplied with a two

roll pivoting dancer with closed loop feed back to a magpartical

clutch creating reliable smooth tension control thru out the

roll build.

|

Dual Position Narrow Web Unwind Stand

The cantilevered winder on the right was designed as a 10"

two position manual unwind stand. This set up can be used to

increase production by alternating between winding position

and loading new product rolls while continuing to unwind on

the other position. This machine can also unwind two webs simultaneously.

Each position is supplied with a leaf type airshaft, pneumatic

brake and air regulator to set tension.

|

|

Options:

- Light, Medium or Heavy duty applications

- Automatic edge guiding or manual positioning

- Winders supplied with AC or DC drives for speed or torque control

Related Products:

US Webcon can modify the above design to meet your specific

needs and requirements. Call us to discuss your application with one

of our engineers at (570) 644-1401.